Woo HOO! It's mid May. Time to seal off the fireplace and build some patio furniture. The boys down at La Belle Sauvage just hit us with the summer projects issue of

Work. My apologies to the Southern Hemisphere.

Since the dawn of time, crafty people have divvied up their elective projects seasonally. Sure, there are a lot of sensible reasons for doing this. For instance, I don't know anybody who'd willingly scrape and repaint the bottom of their bass boat in the dead of winter.

Then again, there are a lot of intangible motivations too. We're all entirely more social when it's sunny and warm, and crafty people get social by making things. The proof is in the magazine.

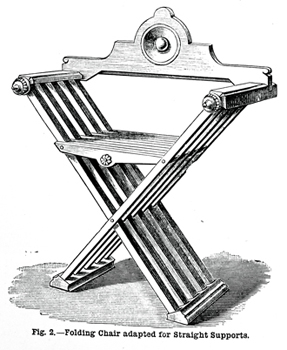

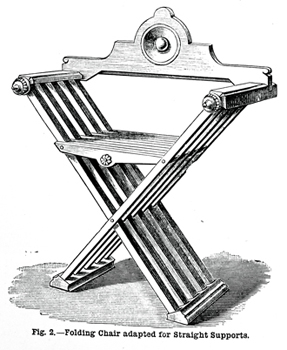

Sealing off the fireplace in an artful and pleasing way wouldn't count for much if you didn't care about outward appearances. Hell, in "A Folding Chair For Hall Or Garden" the author rests the raison d'etre partly on his unwillingness to get in dutch with the wife. See, we're social creatures, notwithstanding predilections for hiding in workshops for long stretches of time.

Having some authorship over the form of objects in our immediate surroundings is one of the ways we speak to the rest of the world. What are we saying?

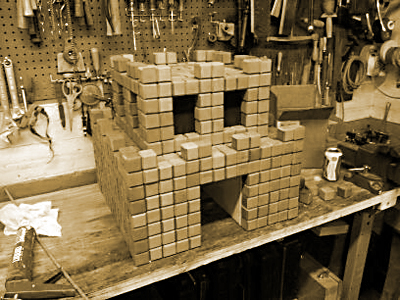

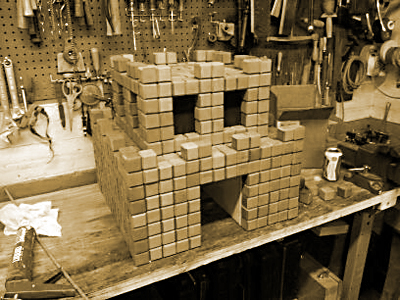

It's an amusing sentiment, but I'll be the first to admit that it's only applicable part of the time. This week, I started my raft of summer projects by chamfering 1,500 wooden cubes. Admittedly, it's not the sort of thing I would have done on my own, but I have friends who continually help me to overcome my personal shortcomings; chief among them being the owner of a table saw blade that isn't dull enough.

What I'm trying to say is that it wasn't my project, but I managed to make it mine, inasmuch as I wound up caring a lot about how things got done. I aspire to proficiency in the field of Manufacturing, so when my friends come to me to ask me if they can use my belt sander for an insane purpose, I direct my energies to devise a method that prevents the summer becoming a reeking rot of smouldering wood dust. Want to see how?

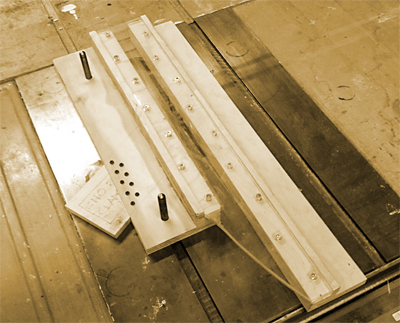

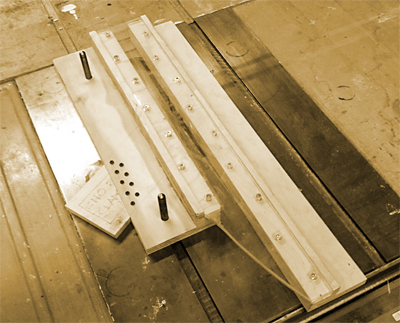

Somewhere, I read that the saw is the most efficient roughing device. I think it was in Holtzapffel, but for the life of me I can seem to find it again. To facilitate our mad task, I put together a table saw fixture consisting primarily of a tunnel (credit where credit is due: this was James's idea, so he gets another point. You can read about his first point in the disclaimer text at the bottom of this entry), but with an integral featherboard to prevent the entire apparatus from becoming a cube cannon, of sorts.

The rest of our machinations pertained to the work flow. Naturally, every cube has 12 edges. To us, that's 18,000 distinct instances of blade-to-cube contact. Test runs allowed us to concoct a system of re-orienting recently cut cubes. We experimented with different arrangements of helpers, and different batch sizes.

In the end, it turned out to be a two-person gig, with helpers standing by to spell the weary. Blocks were processed in batches of 100 or so, but they were divided into sub-batches of 16-cube grids for easy feeding. Steady, rhythmic feed intervals prevented the cube-reorienters (blockers) from being overwhelmed, but we had a number of Lucy-at-the-chocolate-factory moments before we figured that out.

The project is still ongoing but here's a sneak peek before the grand unveiling.

All told, we got the job done in about seven hours, with a nice lunch provided by the fellow who consigned us to our maniac endeavor. Amidst all this reminiscing, I fancy I hear someone saying, "What is the point, blockhead?"

Simply put, summer projects are supposed to be fun. If we can all cop to their inherently social nature, then we can justify putting some effort into making sure things proceed in a manner designed to preserve conviviality. Personally, I'm over and done with having my projects get the better of me. I want to enjoy being a maker, especially when it's warm and sunny.

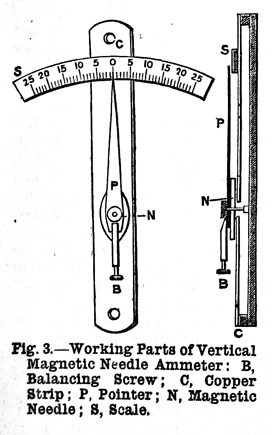

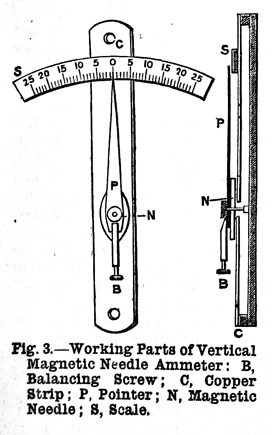

Work is as much about how we work as it's about the projects it presents. So, before your next electroplating party, do the right thing and calibrate your ammeter.

–TIM

ARTICLES FOUND IN THIS ISSUE:

A SUMMER FITMENT FOR THE FIREPLACE &bull NOTES FOR ELECTROPLATERS (Part 5)

A FOLDING CHAIR FOR HALL OR GARDEN • "TIPS" FOR TYROS

JAPANESE MOTIVES FOR FRET CUTTING, STENCILS, AND SIMILAR PURPOSES

BINDING MADE EASY (PART 2) • OUR GUIDE TO GOOD THINGS

SHOP: A CORNER FOR THOSE WHO WANT TO TALK IT

• Click to Download Vol.1 - No. 9 •

Disclaimer: Articles in Work: The Illustrated Weekly Journal for Mechanics describe materials and methods that would not be considered safe or advisable today. We are not responsible for the content of these magazines, and cannot take any responsibility for anyone attempting projects or procedures described therein.

The first issue of Work was published on March 23rd, 1889. The goal of this project is to release digital copies of the individual issues starting on the same date in 2012, effectively republishing the materials 123 years to the day from their original release.

The original printing was on thin, inexpensive paper. There are many cases of uneven inking and bleed-through from the page behind. Our copies of Work come from bound library volumes of these issues and are subject to unfavorable trimming, missing covers, etc. To minimize harm to these fragile volumes, we've undertaken the task of scanning the books ourselves. We do considerable post processing of the scans to make them clear but please bear with us if a margin is clipped too close, or a few words are unreadable. We would like to thank James Vasile and Karl Fogel for their help in supplying us with a book scanner and generally enabling this project to get off the ground.

You are welcome to download, print, and pretty much do what you want with the scan for your own personal purposes. Feel free to post a link or a copy on your blog or website. All we ask is a link back to the original project and this blog. We are not answering requests for commercial downloads or reprinting at this time.

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

Since the dawn of time, crafty people have divvied up their elective projects seasonally. Sure, there are a lot of sensible reasons for doing this. For instance, I don't know anybody who'd willingly scrape and repaint the bottom of their bass boat in the dead of winter.

Since the dawn of time, crafty people have divvied up their elective projects seasonally. Sure, there are a lot of sensible reasons for doing this. For instance, I don't know anybody who'd willingly scrape and repaint the bottom of their bass boat in the dead of winter.